Siemens NX is used to produce the CAM manufacturing program with the NC code. This pillar can create adverse cutting conditions such as vibrations and localized heat generation. A blisk agreement with GE to machine parts for the new LEAP (Leading Edge.

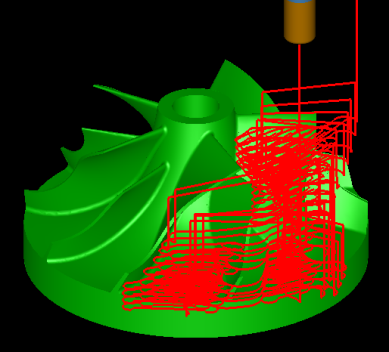

The standard settings for adaptive roughing often leave a pillar at the center of the area being machined. Stock pillar removal for adaptive roughing The toolpath calculation algorithms use "out to in" ordering to remove the material gradually which enables the flatland cycle to machine parts with undercut features. This new option for the flatland cycle enables operators to machine flat undercut areas using slot milling tools.Īdditional toolpath slices are generated on the flat regions of the undercut. The term is used mainly in aerospace engine design. Operators can adjust the variable offset at different locations on the blade to fine-tune the toolpath according to measurement results based on the coordinate measuring machine, without changing the complex 3D file. With the release of Edgecam 2016 R2, the software is now a 64-bit application that offers increased access to memory, which improves overall efficiency, especially when working with large files. A blisk (or bladed disk) is a single engine component consisting of a rotor disk and blades, which may be either integrally cast, machined from a solid piece of material, or made by welding individual blades to the rotor disk. Smooth toolpaths ensure consistent acceleration and, therefore, shorter cycle times. The new blisk module provides parameters and settings for creating very smooth toolpaths for multiblade machining.

0 kommentar(er)

0 kommentar(er)